1、Sludge Drying

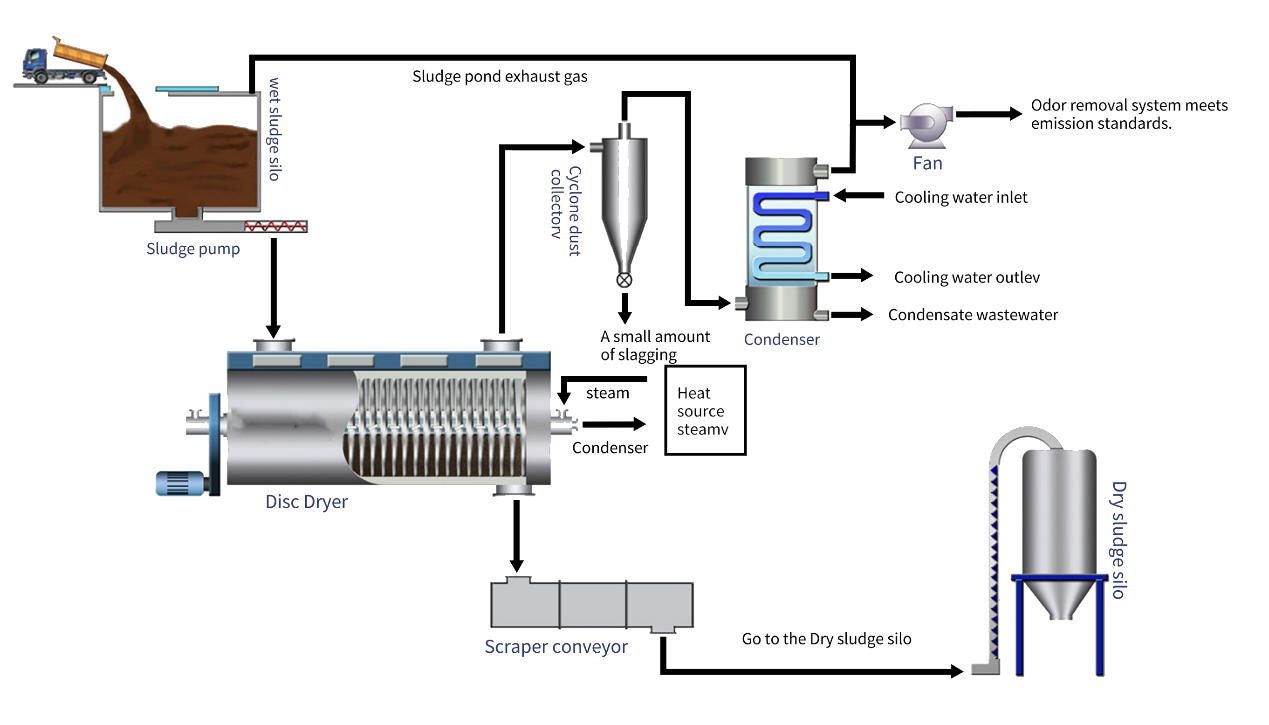

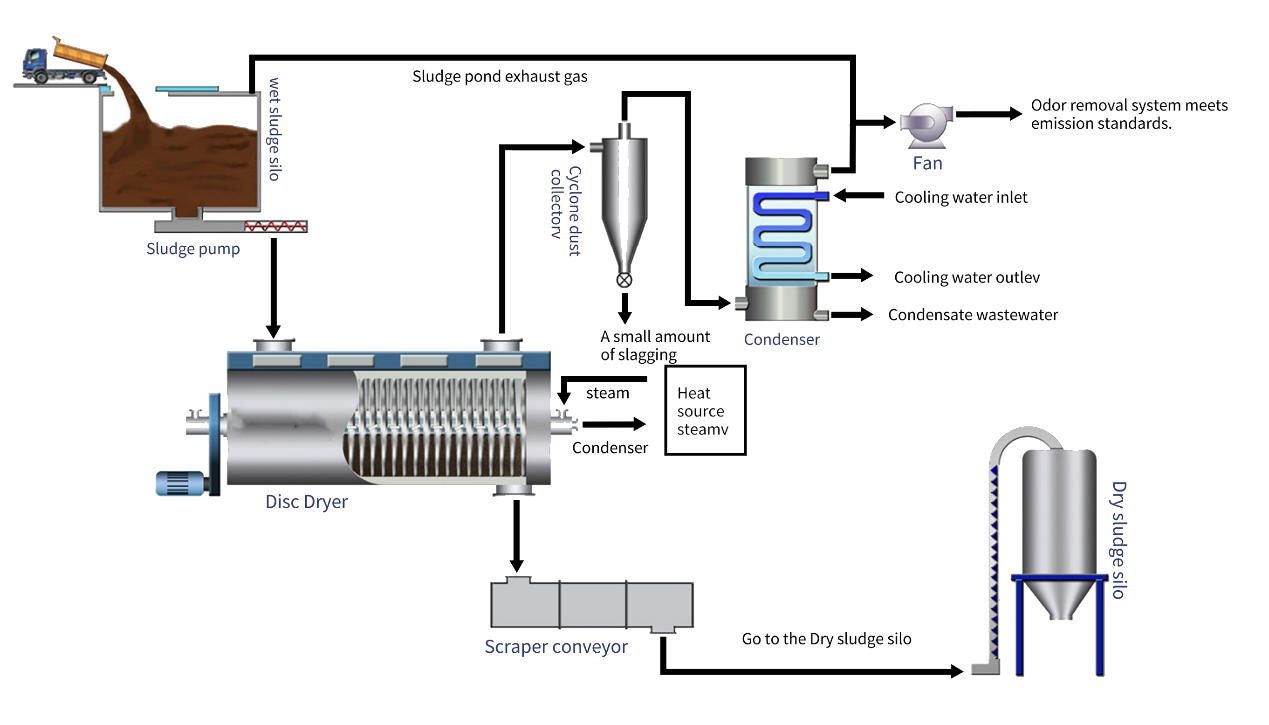

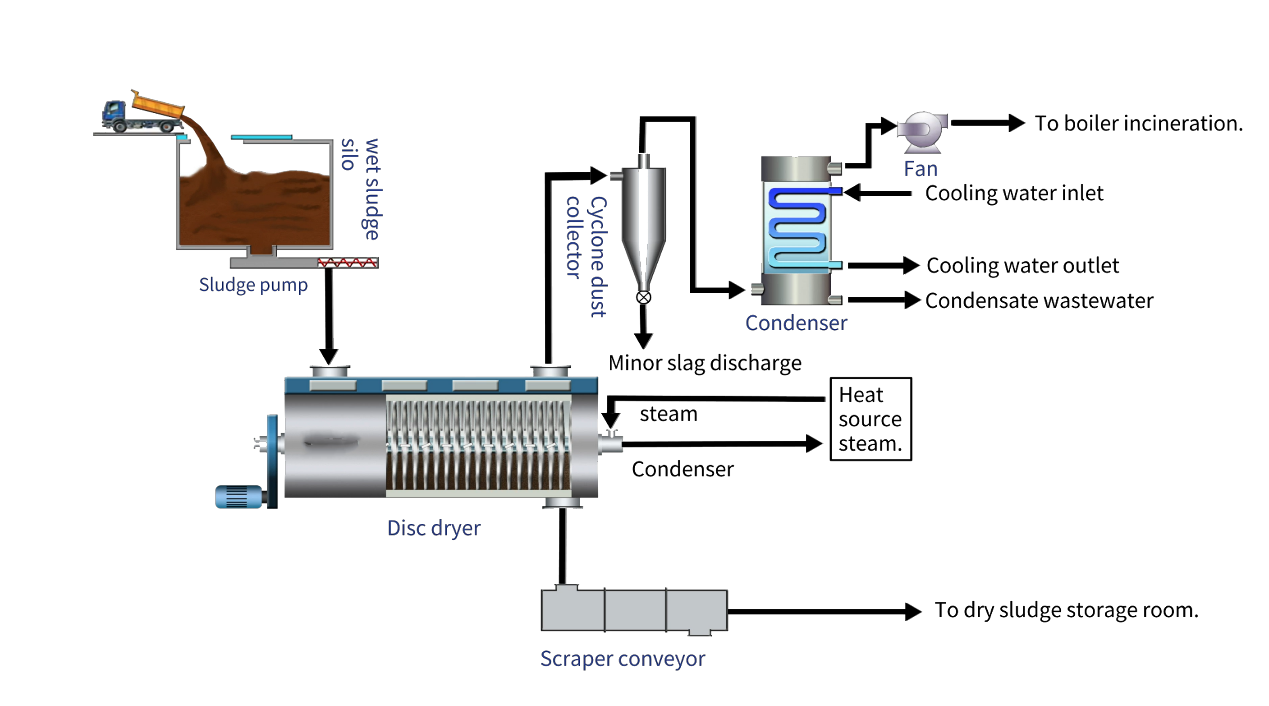

Sludge Drying Process

The truck-mounted sludge is fed into the wet sludge silo, then transported to the disk dryer through a wet sludge conveying device. The steam is used as a heating source, and the heat is transmitted through the jacket, the hollow shaft, and the hollow plate. The sludge is heated and dried indirectly.

The generated water vapor pass through the induced draft fan to the cyclone dust collector, a small amount of slag is discharged, and then the vapor is sent to the condenser to condense the water, and the non-condensable gas is sent to the boiler incineration or deodorization system for treatment and then discharged to meet the standard. The wasted water is sent to the sewage treatment system through the collection-device and it's discharged after reaching the standard.

The dry sludge is transports to the dry sludge silo through the conveying device for temporary storage.

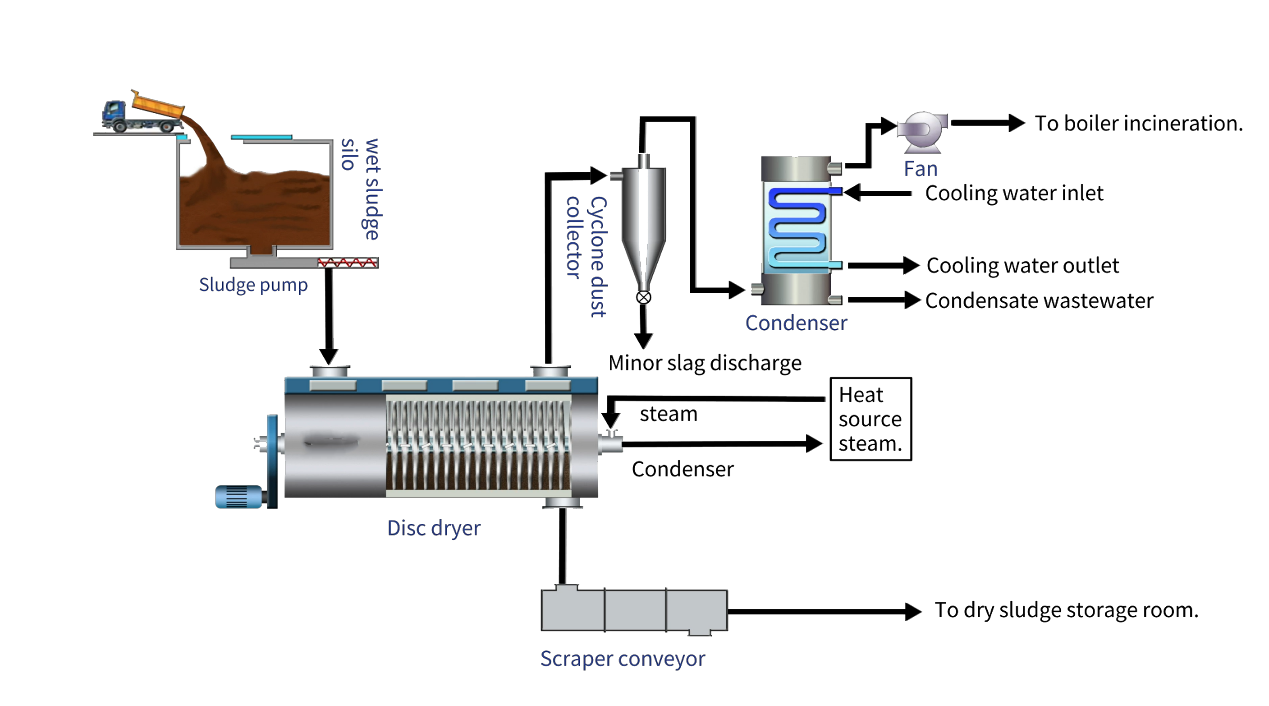

Thermal Power Plant/ Refuse Power Plant Collaborative Disposal Process

Thermal Power Plant/ Refuse Power Plant Collaborative Disposal Process

Co-processing sludge with thermal power plants can not only use the steam after power generation by the thermal power plant as the drying heat source (find the most suitable heat source according to the parameters), but also use the existing incineration and tail gas treatment equipment to save investment and operating costs. The dried sludge is transported to the coal yard and evenly mixed with coal, and then enters the boiler for incineration through the coal conveying system of the power plant.

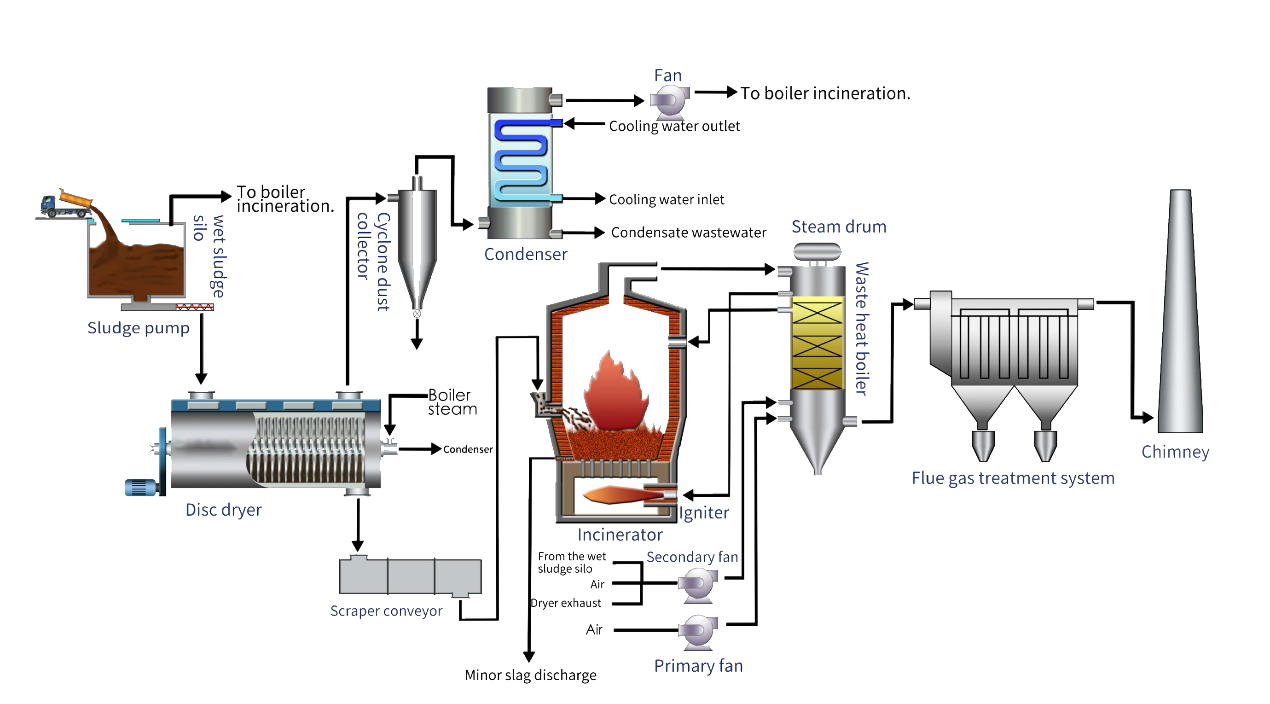

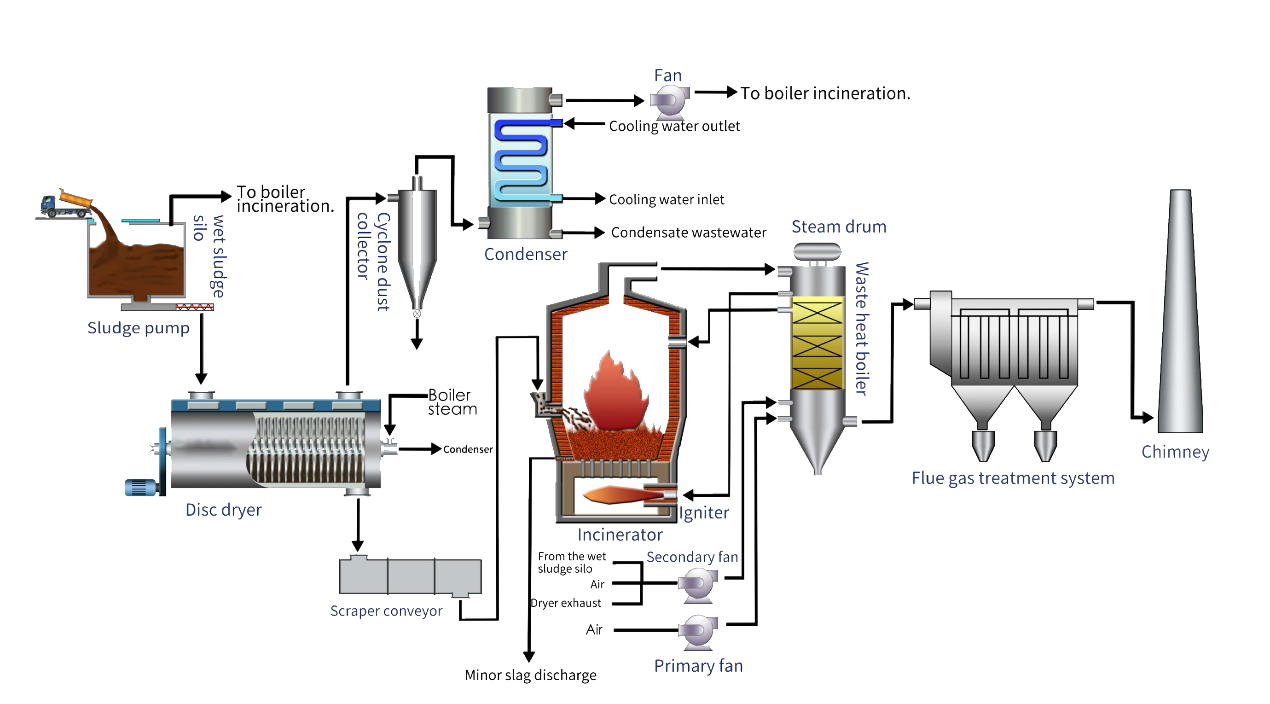

Drying Incineration Process

Drying Incineration Process

Fluidized bed incineration of sludge is a good solution. Due to the strong turbulence, long gas turbulence time, and uniform temperature distribution, efficient incineration can be achieved at relatively low temperatures and with less excess air, resulting in high destruction and removal rates of harmful substances. By grading combustion and adding alkaline substances, the content of acidic substances (SOX and HCL) in the flue gas can be greatly reduced.As a high-heat load technology, fluidized bed incinerators are easy to scale up, have long service life, no high-temperature equipment, and low operating and maintenance costs. The system consists of sludge conveying system, sludge drying system, incinerator, waste heat steam boiler, flue gas treatment system, ash collection and conveying system, etc.

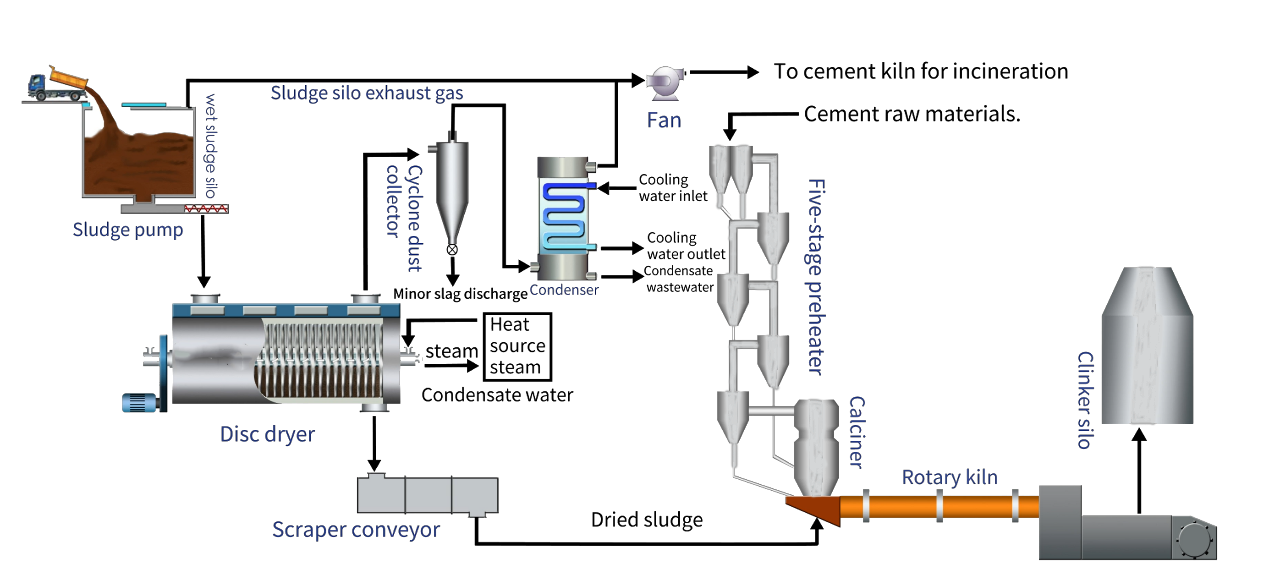

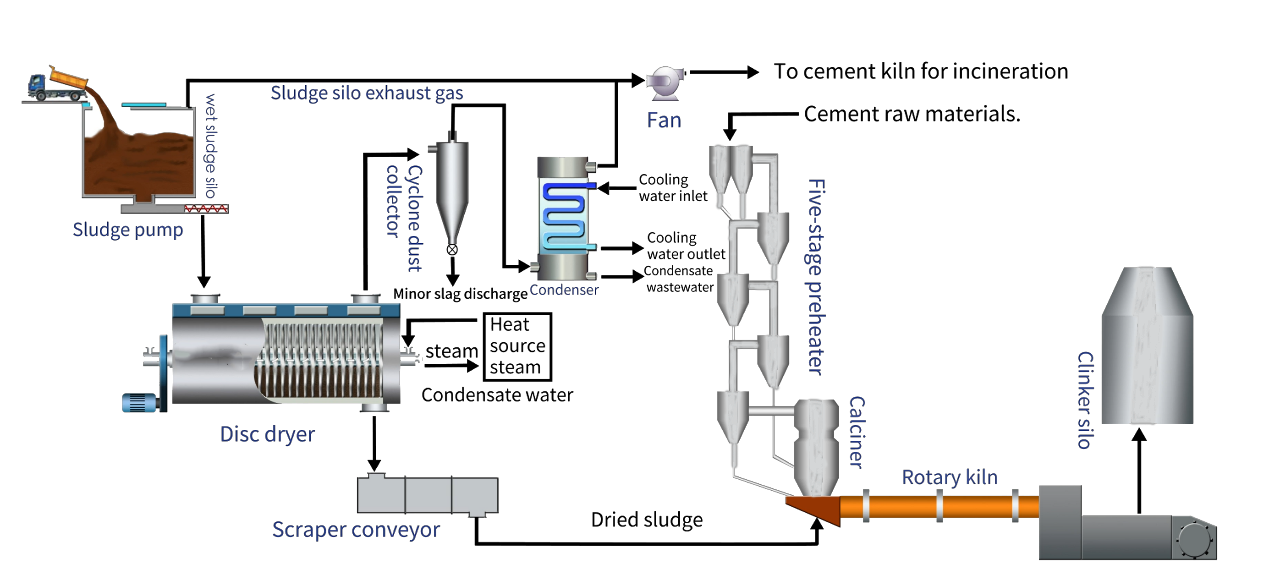

Cement Kiln Collaborative Disposal Process

Cement Kiln Collaborative Disposal Process

Wet sludge is transported by a sludge truck to the wet sludge silo, and then pumped into the dryer. The exhaust steam from AQC or SP boiler or back- pressure steam turbine is used as the heat source for the dryer. The wet sludge is quantitatively fed into the dryer, and is stirred and fipped by the slow rotation of the disc to constantly update the heating interface and fully exchange heat with the heated body and disc, so that the surface moisture in the sludge evaporates. At the same time, the sludge is pushed towards the outlet by the guiding mechanism during transportation, and is continuously stirred to ensure complete drying. The dried sludge is discharged from the outlet and transported as auxiliary fuel to the cement rotary kin for incineration disposal.

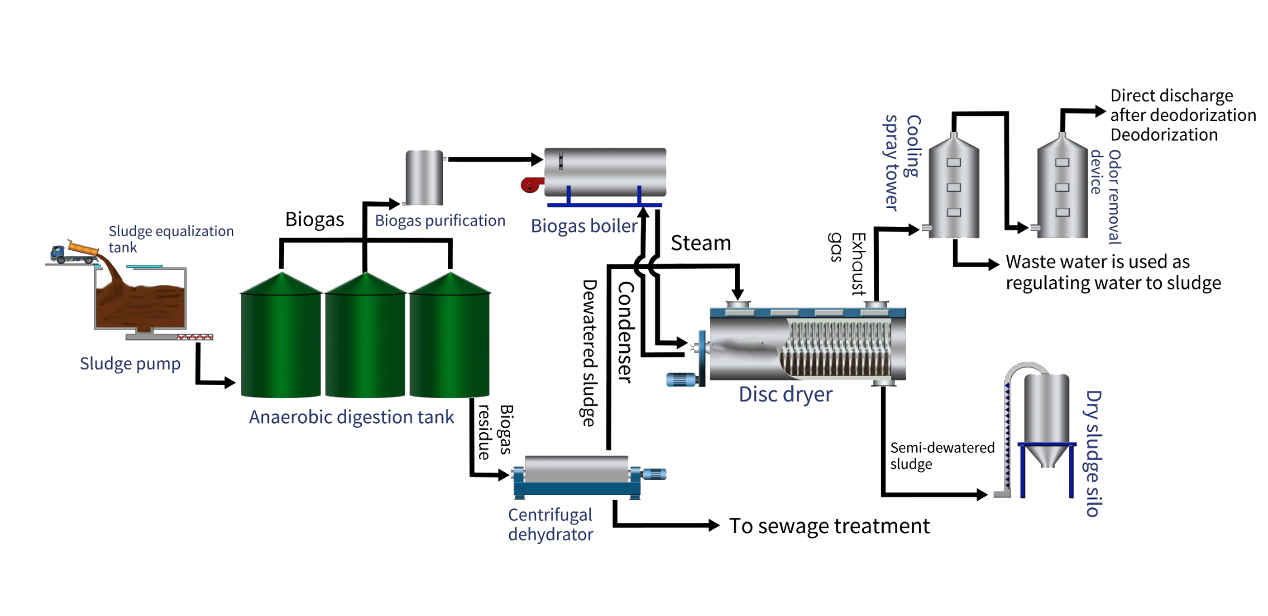

2、Kitchen Biogas Residue Drying

2、Kitchen Biogas Residue Drying

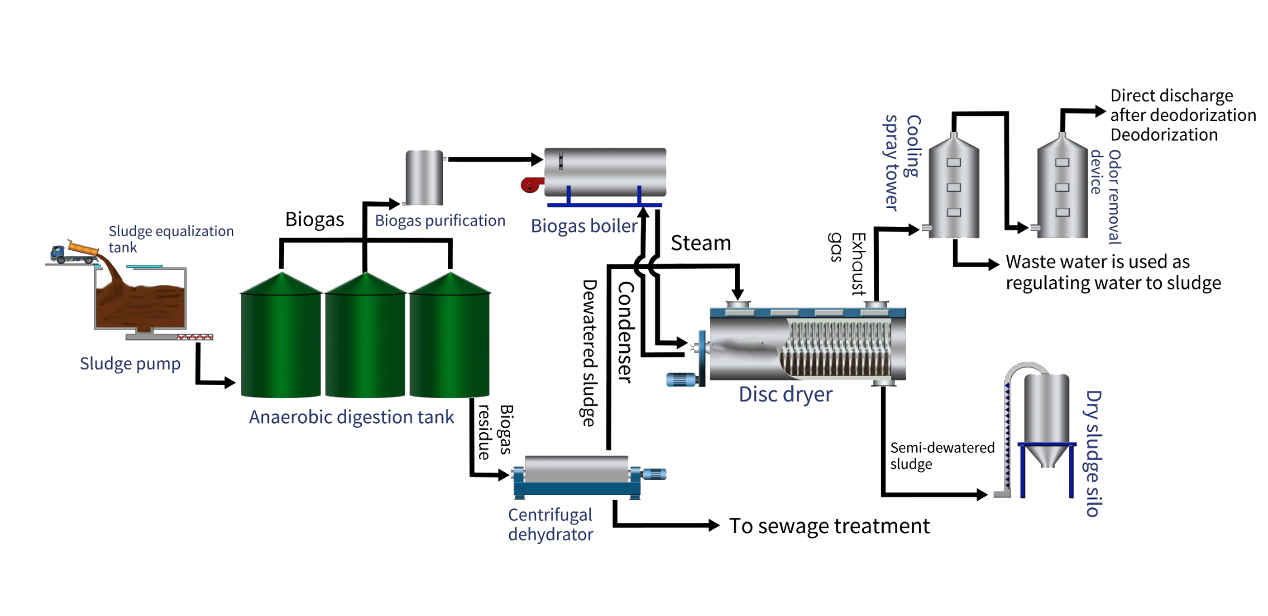

Kitchen Biogas Residue Drying Process

A new process scheme of material digestion+semi-drying system is put forward.

The system includes two core sections, one is the anaerobic digestion system of materials, the other is the drying system of materials. Combination of the two conforms to the national kitchen biogas residue disposal policy requirements and the general idea, thoroughly implement the Kitchen biogas residue treatment and disposal of harmless, stabilization, reduction, resource processing route.

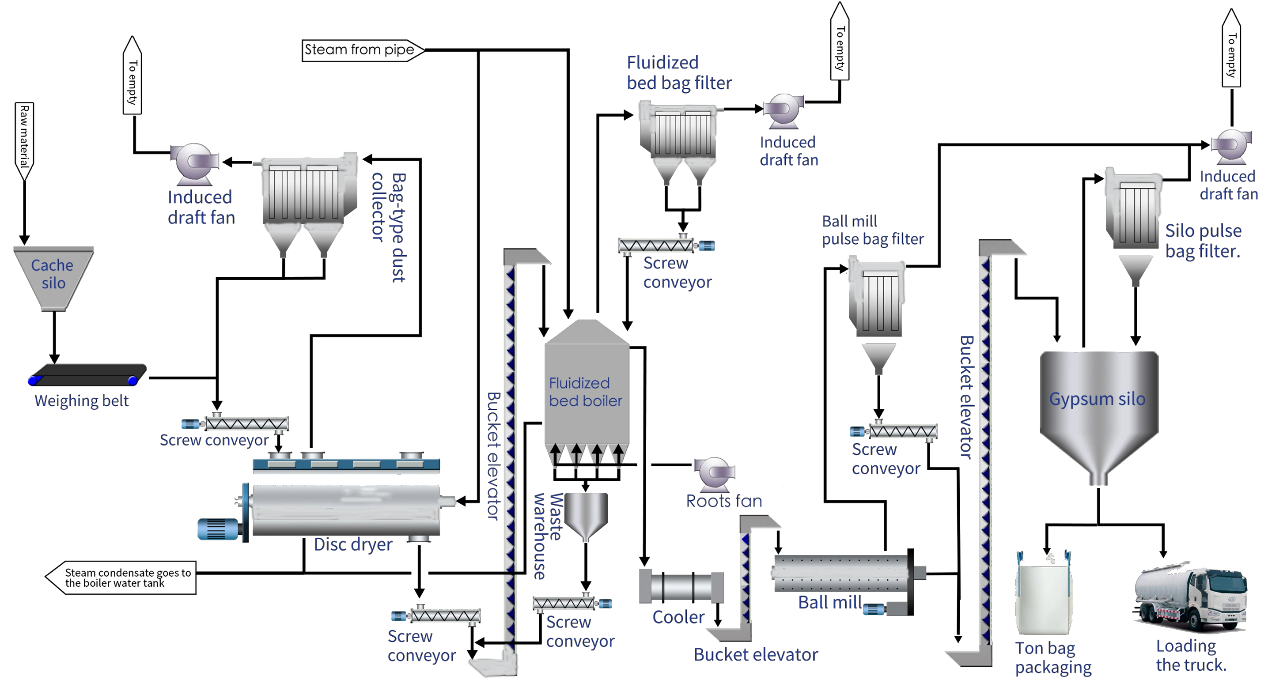

3、Gypsum Drying

3、Gypsum Drying

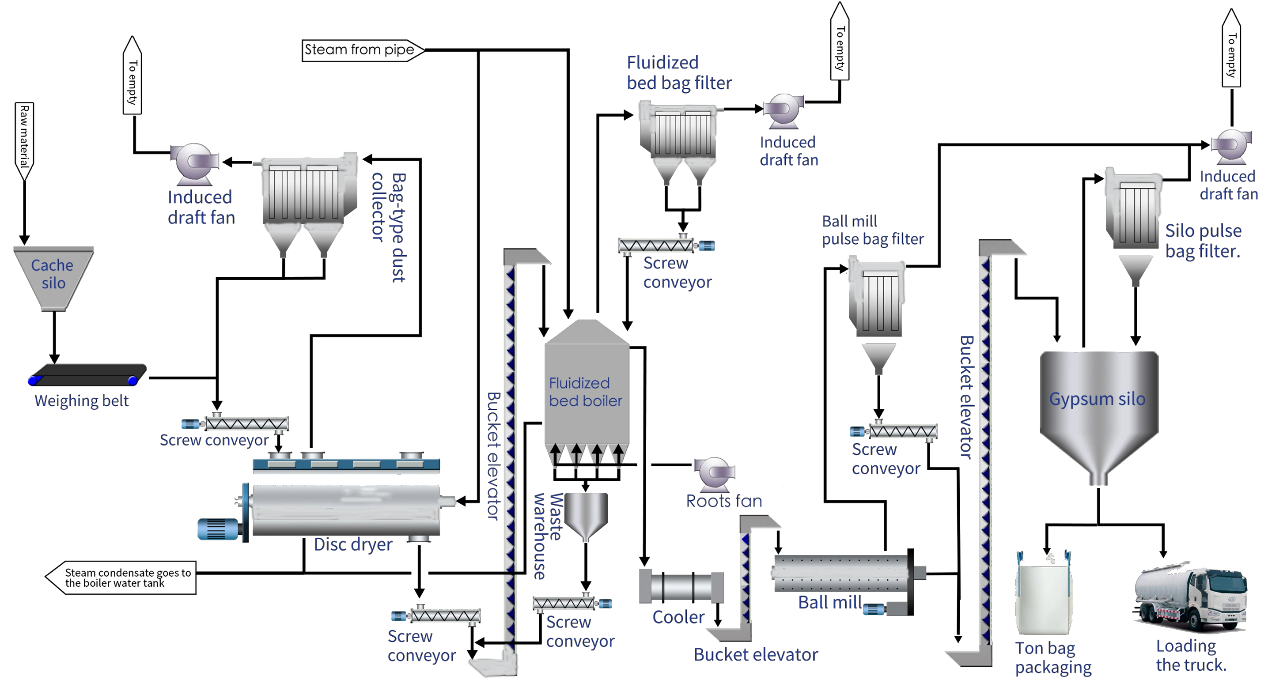

Gypsum Drying Process

After desulfurized gypsum is transported to the cache silo, it is screened and weighed by belt. Then the material is evenly sent to the disc dryer for drying. And then screw conveyor and bucket elevator input into the furnace for calcining into Building gypsum. The building gypsum from the furnace is transported to the ball mil through the conveying equipment. The metal ball in the ball mill constantly impinges with the building gypsum to realize the pulverized of the building gypsum, and then sent to the gypsum silo for storage. There are bulk machine and ton charter at the bottom of the silo, which can realize bulk and ton packing and small bag packing.

4、Other Material Drying

4、Other Material Drying

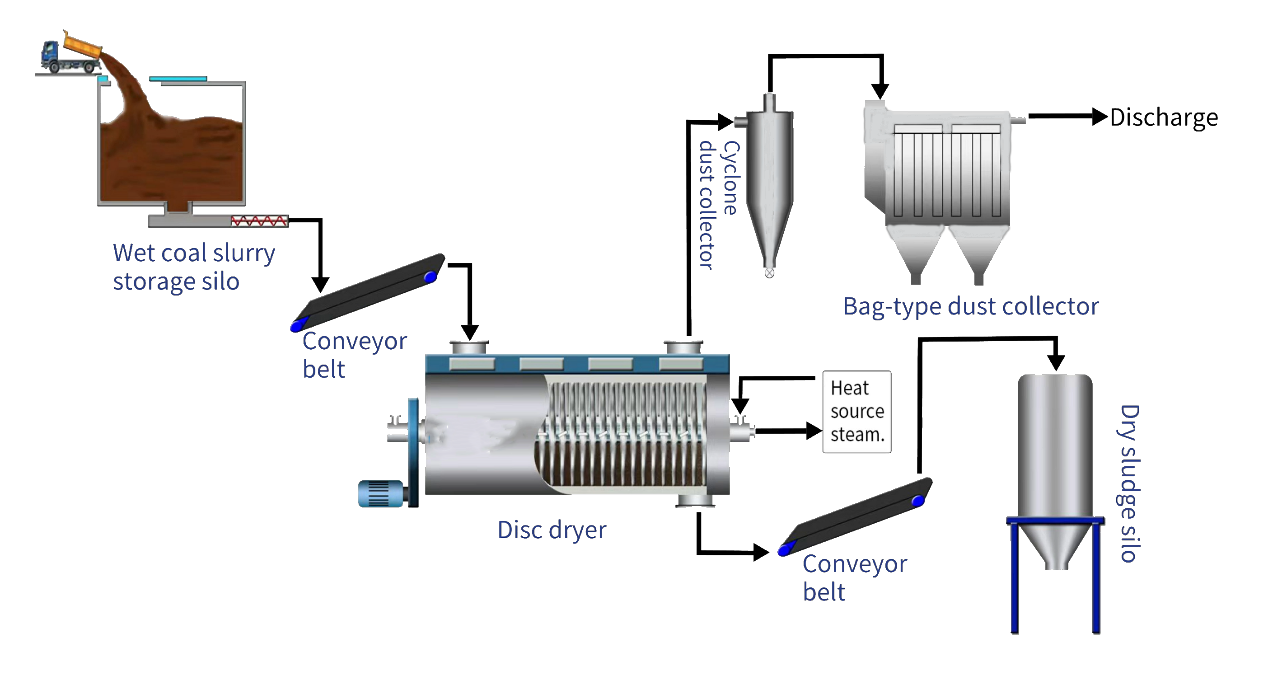

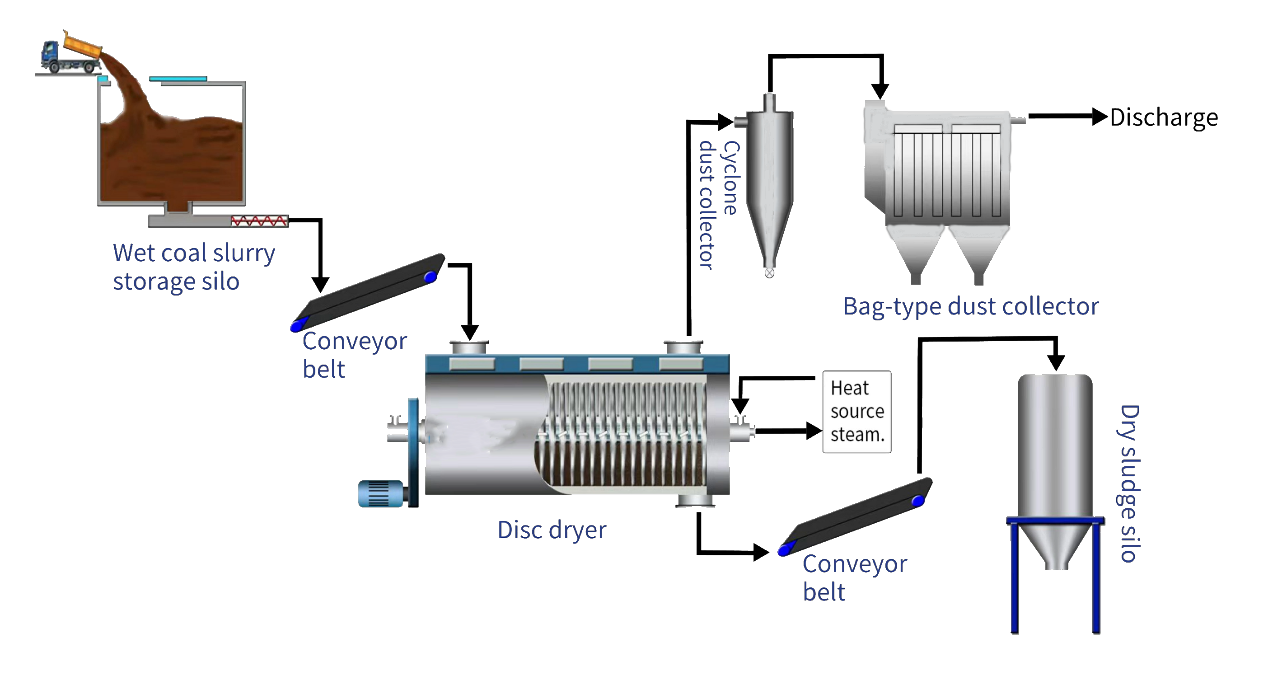

Coal Sludge Drying Process

The vehicle-mounted coal sludge is sent to the silo,and then sent to the disc dryer through a conveying device. Saturated steam is used as a heating source, and heat is transferred through the jacket, hollow shaft and hollow disc on the shaft. The sludge is heated and dried indirectly, the water vapor generated by the system induced draft fan to the cyclone dust collector + bag-type dust collector, with a small amount of residue discharged. The dried sludge is transported to a dry sludge silo through the conveying device for temporary storage wait for subsequent disposal.

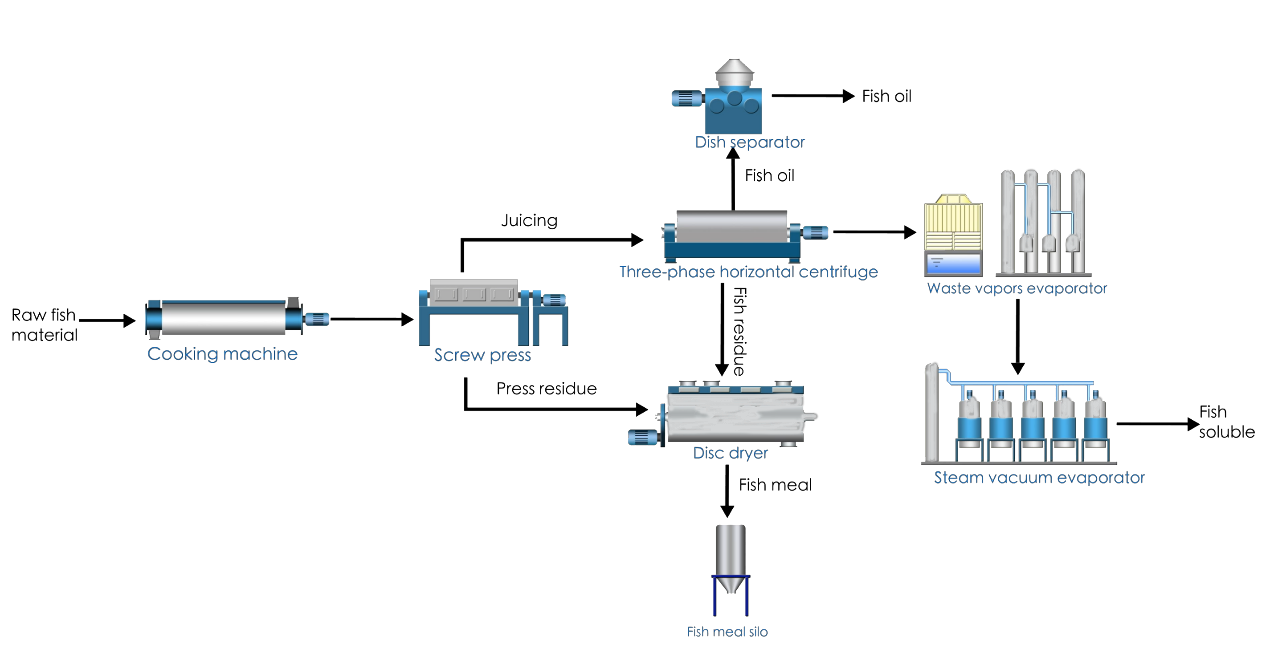

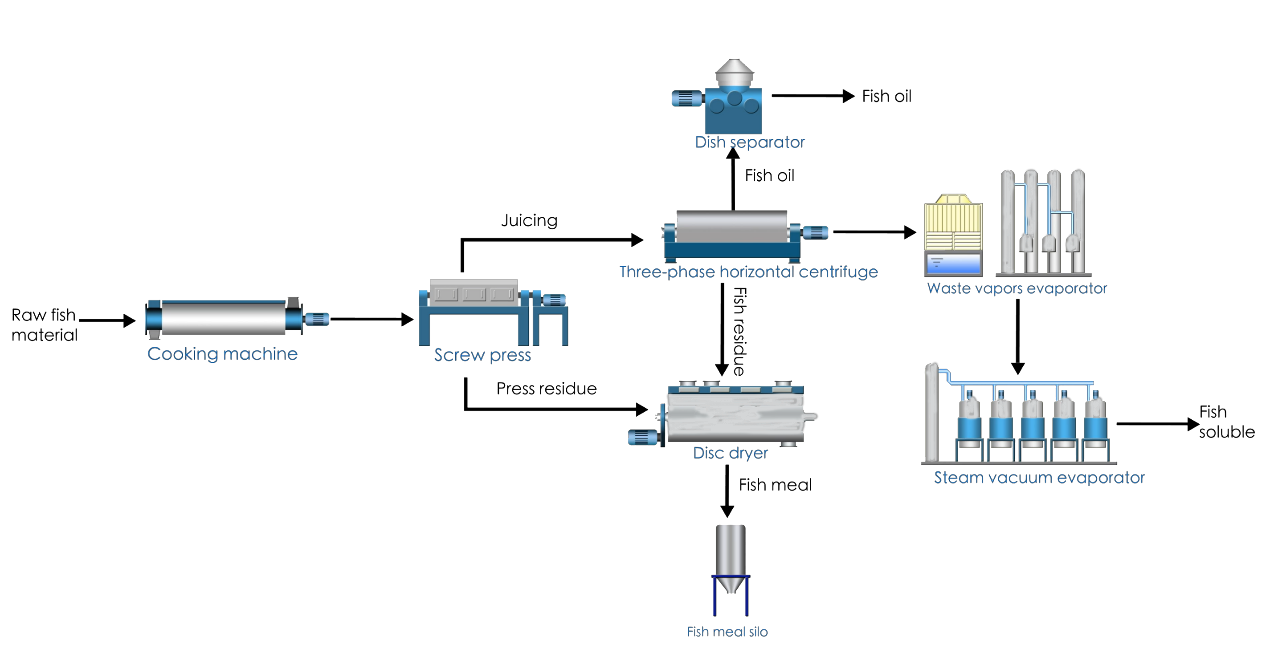

Fish Meal Drying Process

Fish Meal Drying Process

The fish meal dryer is a device that uses a heat source (usually steam) to dry the solids produced during the steaming process to obtain fish meal. The processing of fish meal generally goes through processes such as steaming, pressing, separation, drying, and grinding. One or more types of fish are usually used as raw materials for processing, such as raw fish, fish filets, and scraps. After being separated by a magnetic separation device, they enter the hopper and are continuously fed into the cooking machine through a screw conveyor. After cooking, the material enters the press directly, and after being pressed by the twin screw, the press juice enters the juice pool, and the press residue enters the dryer. The protein water is concentrated and added to the dryer for drying together. The squeezed juice is preliminarily precipitated and then sent to the heating tank. After being heated to a certain temperature, it is sent to a three-phase horizontal screw centrifuge to separate the fish residue and fish juice. The fish residue is recovered into the dryer, and the fish juice is sent to a disc separator for oil-water separation. The fish oil is obtained through further processing to obtain the finished product fish oil.